CNC panel bending machine, It has high quality, high speed and high efficiency bending function, and is generally suitable for automatic bending of box type sheet metal parts. CNC panel bending machine adopts servo-controlled folding and pressing device, Open structure for easy side unloading.

The main motion of bending can be divided to 3 axis, which are respectively the pressing axis, up-and-down swinging axle and forward/backward moving axis. Under the control of CNC system, different motion paths can be run in any combination, thus forming different bending process combination.

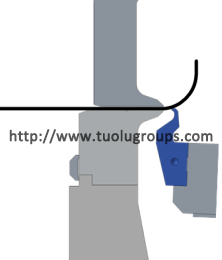

Universal bending dies, bending machine adopt it to realize positive and negative angle bending, large arc, hemming bending, and high efficiency bending of complex section workpiece. Made of die steel, the die adopts high precision processing technology ensures the accuracy and reliability of bending, and the special manufacturing technology ensures the small wear of the die.

1)positive bending 2)negative bending 3)hemming 4)large arc.

Servo-driven bending device, three axis ganged, can achieve a variety of motion track efficient folding. For different materials, different thickness, system can automatically execute different gaps and trajectory. This equipment is energy-saving, environment-friendly, low energy consumption and low noise. Adopting advanced processing technology, processing efficiency is improved obviously, with stable and reliable mechanical structure. The pressing device adopts two-way servo pump control technology, with high speed and low energy consumption. Vertical motion to avoid the impact on the minimum size of the workpiece. The crowning compensation mechanism adopts the special patent structure and has the function of compensating the deformation of the horizontal crowning of die.

1. Technical specifications

l Min. sheet metal size:250*200mm

l Max. bending height:200mm

l Max. bending length:1400-3000mm

l Max. diagonal dimentions:1850mm

l Max. processing thickness:1.2mm(Q235A),0.8mm(SS),1.6mm(AL)

l Min. processing thickness:0.5mm

l Max. Bending speed:0.3s/bend

2. Bending specifications

| Items | Unit | Specification | Remark | |

| Max. bending length | mm | 1400-3000 | ||

| Max. bending thickness | MS δb=410MPa SS δb=660MPa AL δb=265MPa |

mm | 2.0 1.0 3.0 |

|

| Min. bending thickness | mm | 0.5 | ||

| Bending height | mm | 165 | ||

| Bending straightness | mm/m | ±0.4 | ||

| Thickness of curved arc | - | 0.8-1.2 | ||

| Positioning precision | mm | ±0.2 | ||

| Single step bending speed | s | 0.3 | ||

3. Manipulator

- The functions of changing sides, rotating and moving are realized in the horizontal plane

- C-type structure, more flexible and freer space

- Servo driver, linear guide, high precision

Bending manipulator has the function of positioning and rotary transportation of sheet metal. The utility model is composed of a central positioning device, a rotating device, a clamping device, a mobile conveying device and a base. After the sheet is in place, it realizes the function of centering and pressing, and cooperates with the main machine of folding to realize various folding process actions.

Positioning pushing device will place the plate to be folded in the X and Y directions, which can realize the pre-positioning between the plate and the machine tool. There are two groups of positioning blocks, which can locate the corner and the edge respectively. The combination has nine positioning functions, and the Y direction of the left and right positioning seat can be adjusted (+50mm) to adapt to the positioning function of various sheets.

Compressing device realizes reliable compaction by servo-driven screw driving connecting rod, and can realize reliable clamping of plates of different materials and thickness.

Rotating device realizes the rotation of the rotating block by servo driving motor and reducer. The high precision encoder realizes closed-loop control, and the rotation accuracy is stable and reliable.

4. Main technical specifications

| Items | Name | Specification | Unit | ||

| 1 | Maximum bending length | 1400-3000 | mm | ||

| 2 | Maximum bending height | 200 | mm | ||

| 3 | Maximum diagonal dimension | 1850 | mm | ||

| 4 | Bending thickness | MS δb=410MPa | 2.0 | mm | |

| SS δb=660MPa | 1.0 | mm | |||

| AL δb=265MPa | 3.0 | mm | |||

| 5 | Minimum bending thickness | 0.5 | mm | ||

| 6 | Maximum sheet size | 1500 | mm | ||

| 7 | Range of bending angle | -130~130 | ° | ||

| 8 | Height of worktable | 840 | mm | ||

| 9 | Max. feeding speed of manipulator | 1000 | mm/s | ||

| 10 | Max. rotating speed of manipulator | 60 | rpm | ||

| 11 | Air pressure | 0.7 | Mpa | ||

| 12 | Air consumption | 63 | NL/min | ||

| 13 | Dimensions | Length | 3400 | mm | |

| Width | 2200 | mm | |||

| Height | 2450 | mm | |||

| 14 | Weight of machine | 9500 | kg | ||

5. Main structure and feature

Company independently designs, imported key drive and control parts. The unit mainly consists of loading pallet, loading device, plate conveying device, flanging machine, feeding machine, discharging device and electrical control system.

High strength frame

◆ The frame adopts an open "C" structure, which is good for opening. The frame is made of steel structural parts, and after welding, the internal stress is removed by tempering the large tempering furnace.

◆ By finite element analysis, the frame has high strength and low deformation

Mechanical servo bending system

◆ Using the link type flanging mechanism, high transmission rigidity and good precision can be achieved.

◆ Process adjustment is convenient. Under the control of numerical control system, various folding modes can be realized and have safety protection function.

◆ The stroke and speed of the servo folding beam can be adjusted according to the processing requirements, so that higher comprehensive folding efficiency and better folding quality can be achieved.

Standard worktable

◆ Composite steel ball, brush work table, reduce resistance and surface damage effectively.

◆ Tilting table is more convenient to maintain.

Automatic loading system

◆ Adopt new feeding system, adopt servo drive positioning, high efficiency and smooth operation.

◆ Compact layout, beautiful and simple, high reliability, saving space

◆ Standard panel thickness measuring device can effectively solve plate adhesion.

Unloading system

◆ Under the shear part, there is a special steel belt output channel for the residual waste, which can avoid the failure of the feeding belt of the slender waste card.

◆ There are 2 outlet channels for workpiece: lateral tilting transportation, which is convenient for manual material collection; Roller conveyor forward transmission, left plate follow-up processing interface.(additional optional equipment can be used to add robot blanking and stacking, welding system, etc.)

6. Main parts list

| Items | Name | Brand |

| 1 | CNC system | Self-development |

| 2 | Feeding servo motor and driver | Self-development |

| Linear guide and ball screw | Taiwan PMI | |

| 4 | Air processing quad | Japanese SMC |

| 5 | Bearing | Japan NSK |

| 6 | Breaker, contactor | Germany SIEMENS |

| 7 | Button | France Schneider |

| 9 | Proximity switch | France Schneider |