|

|

| Main Features: |

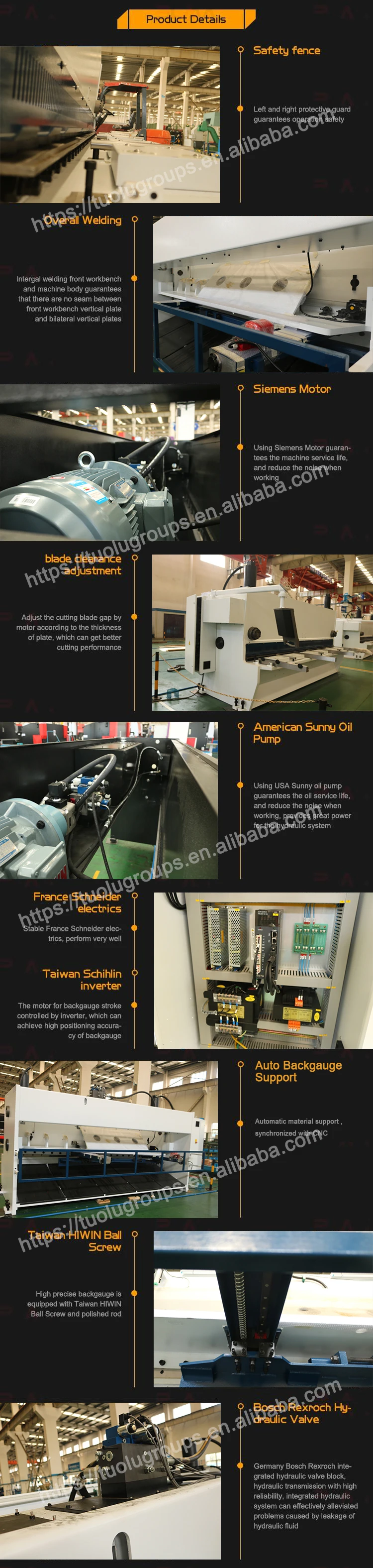

| 1. The entire machine frame is processed by Germany SHW pentahedron processing center at one time |

| 2. Adopts Delem DAC360 CNC system T&L High Precision Plate Guillotine Shearing Machine Price with DAC310 CNC system |

| 3. Adopts Germany BOSCH integrated hydraulic system |

| 4. The shearing angle can be easily adjusted through programming to avoid the deformation of the workpiece caused by cutting |

| 5. The upper beam stroke length can be automatically adjusted to realize the fast and precise cutting of short and small workpiece in order to improve working efficiency |

| 6. The CNC system will automatically adjust the blades gap according to the different sheet thickness and material to improve cutting quality |

| 7. Four-side shearing blade is adopted to improve the service life of blade which is much better than that of swing shear |

| 8.New design of backgauge,stable structure,improve Wear resistance |

Product Overviews

Our Services

| 1. Standard Service: |

|

Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. |

| 2. Installation: |

|

Our factory can send our engineer to the customer’s factory install, commission and training freely .The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely. |

| 3. Quality Guarantee: |

|

Our guarantee time is 36 months from B/L Date ,If any component is damaged during guarantee time,we can send the component to the customer By DHL,TNT freely. |

| 4. Order Processing: |

|

Packaging & Shipping

FAQ

|

Requirement for Customer: |

| 1. Hydraulic oil: imported VG46# anti-wear hydraulic oil; and the required oil mass depend on the machine specification |

| 2. Environment temperature: 0°C - +40°C |

| 3. Environment humidity: relative humidity 20-80%RH(non-condensing) |

| 4. Keep away from the strong vibration source and electromagnetic interference |

| 5. Prepare the foundation according to the foundation drawing |

| 6. Voltage fluctuation 10%--5% |