Why you need a high power Fiber laser cutting machine

Increased Cutting Speed and Piercing Speed

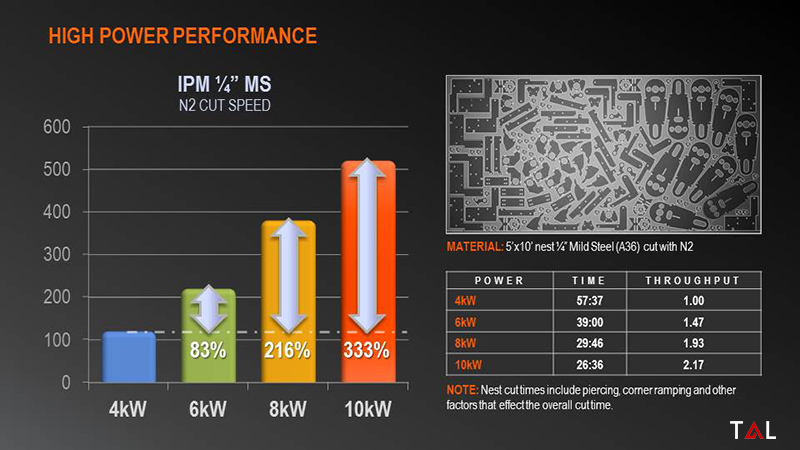

Another advantage of high power fiber laser are the cutting efficiency which increase capacity. High power cutting speed is most effective in mid-range material of using air or nitrogen, especially from 1/8” to ½”.

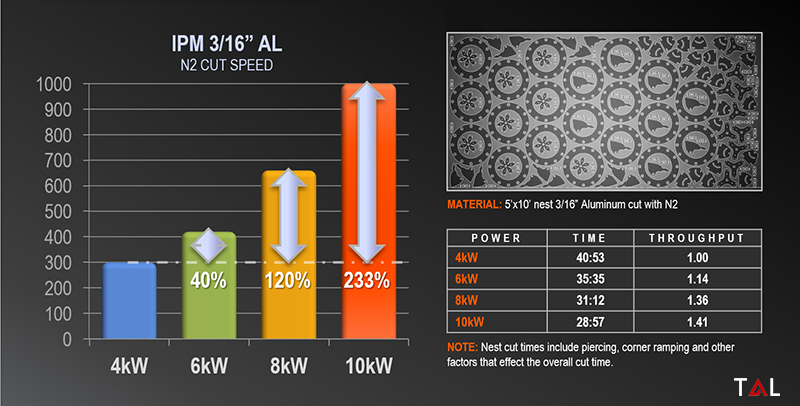

For example, the left side of the photo above shows cutting speed for a single part of 3/16” aluminum. 10kw fiber laser source is 233% faster than 4kw fiber laser source for this single part. If aluminum is not your main product, check out the mild steel example below please.

While a single part speed is impressive, another reliable reference is running a full nest to show the overall improvement. Which include piercing, fine power ramping on the corners. And additional movements that affect the overall cut time of a full sheet.

The right side of the photo shows a full 5’ x 10’ nest of 3/16” aluminum by using 4kw, 6kw, 8kw, and 10kw fiber laser power levels. This nest took 40 minutes and 53 seconds to cut with 4kw laser source. For the same exact nest, the 10kw laser source only take 28 minutes and 57 seconds. With 10kw, you can cut almost an additional half sheet in the amount same time it takes from 4kw to run the full nest. Please check the mild steel example below.

Piercing techniques are also put into use on high power laser’s speed. For example, with a 6kw laser, you can pierce 1” mild steel at 3 seconds, but now with the 10kw it is less than a second. This is also very important for full nest times because if you have a lot of parts or your parts require many piercing, it will be a great promotion of your nest cutting efficiency.